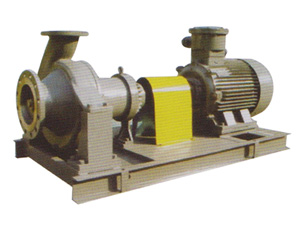

CQB-H Series Magnetic Drive Pumps

These pumps were originally developed by our company to maximize pumping efficiency while minimizing environmental impact. Differing from traditional pump designs, grease can be used as a lubricant in the bearing. The no-seal design effectively prevents transferred liquids from leaking and polluting the environment. The flow passage uses corrosion-resistant materials like Ni-Cr alloy, titanium alloy and stainless steel in order to avoid problems like corrosion, abrasion or cavitation. The power rate can be adjusted within 0.33-50kW according to the material being transferred. The core parts are encapsulated inside by a distance sleeve so that the material transferred will not come into direct contact with the air.

Technical Parameters

- Shaft seal type: magnetic drive

- Casing & impeller materials: 304, 306L stainless steel

- Distance sleeve materials: 304, 306L stainless steel, C276, Ti718

- Max rated pressure at 20℃: PN16

- Max fluid temperature: -45℃/+180℃

- Max flow rate at 2900 rpm: 200m³/h

- Max head at 2900 rpm: 50m

- Allowable medium density range: ≤1.84g/cm3

- Power range: 0.33~50kW

- Others: available on request

Common Applications

- Refinery Industry

- Chemical Processing

- Fine Chemical Processing

- Metallurgical Industry

- Food Processing

- Fiber Processing

- Pharmaceutical

- Electroplate Industry

- Paper Industry

- Electric Power Industry